Hi everyone,

this post is about getting the good old CP200 back working smooth.

The CP200 is a great panel, and almost undestroyable – but after a couple of years, balls and rings might get a little loud and scratchy and need a little love, to get them back smooth and silent again. Although the CP200 is not being manufactured any more, list price for all 4 panels is still around 13k, so keeping them alive as long as possible is probably not the worst idea ;-).

So here’s a couple of steps, that you can do easily on your own to

get there – it’s basically just about cleaning and lubricating wheels and rings again – no rocket science.

Main things we need is a small phillips- and also small hex-screwdriver bit,

then some silicone-spray (for the balls) and some grease (non-plastic-aggressive) for the rings.

And of course something to clean up every component.

Okay, so first thing to do (obviously) is to get rid of all the screws holding the bottom case.

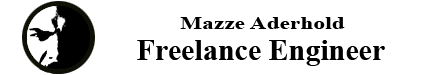

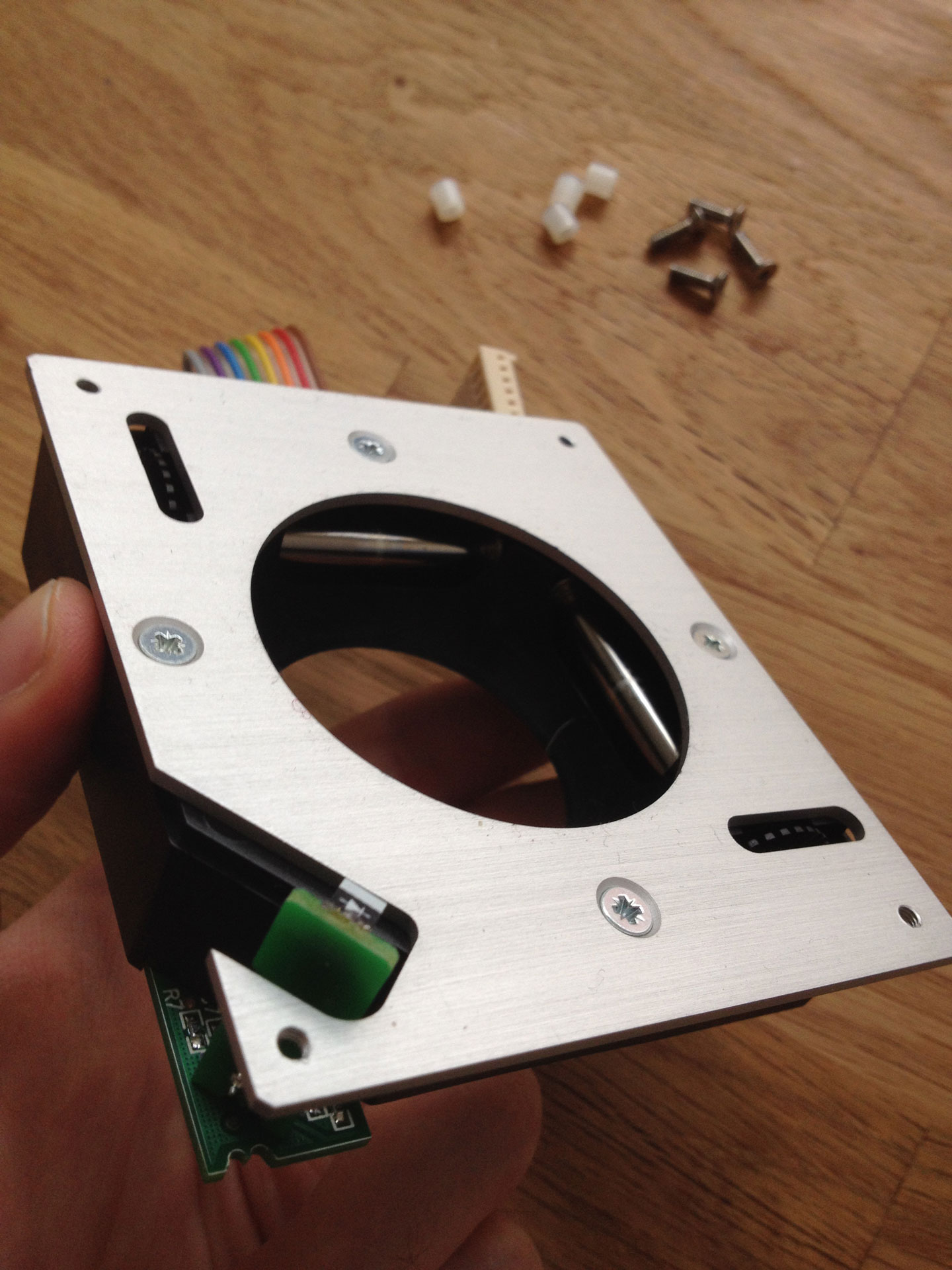

After taking it off, you can see the wonderful rainbow-colored flatband-cables and colorballs.

Loosen the cables and screw off each of the 4 screws holding one of the three ball-caddies.

Make sure to not take off the green bottom-plate, but rather mount off the complete caddie, incl. ball and ring.

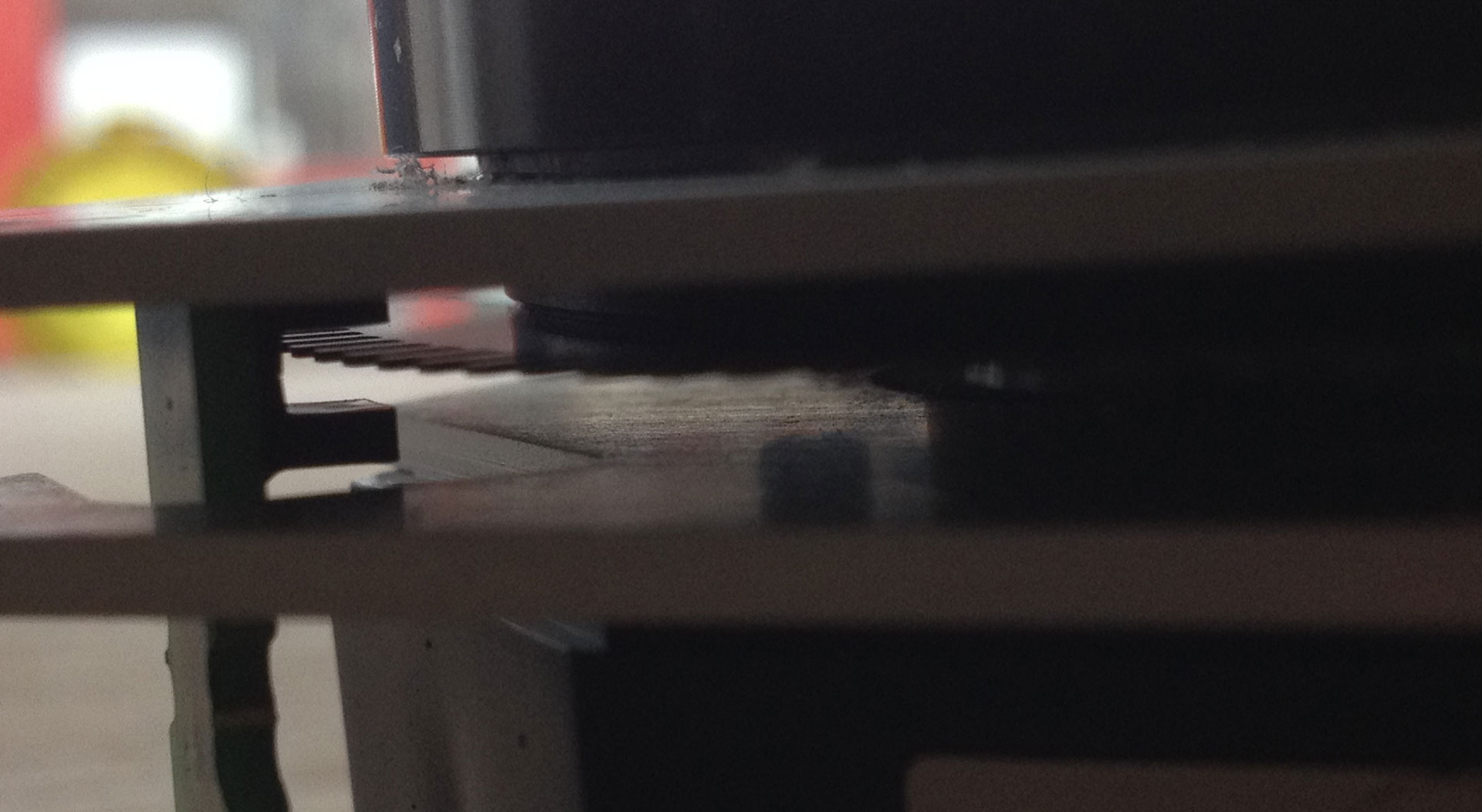

Then, with the hex-driver, remove the 4 screws holding the top-plate onto the bottom of the caddy.

Be careful to not loose the white spacers beneath each screw, and when taking off the ring-plate,

keep an eye on the ring-read-element (not sure what that thing is called actually),

to not damage either the read-element, or the thin metal sheet going through it.

You might try to remember how exactly you got those two apart, because getting the metal sheet back in there will be a little tricky.

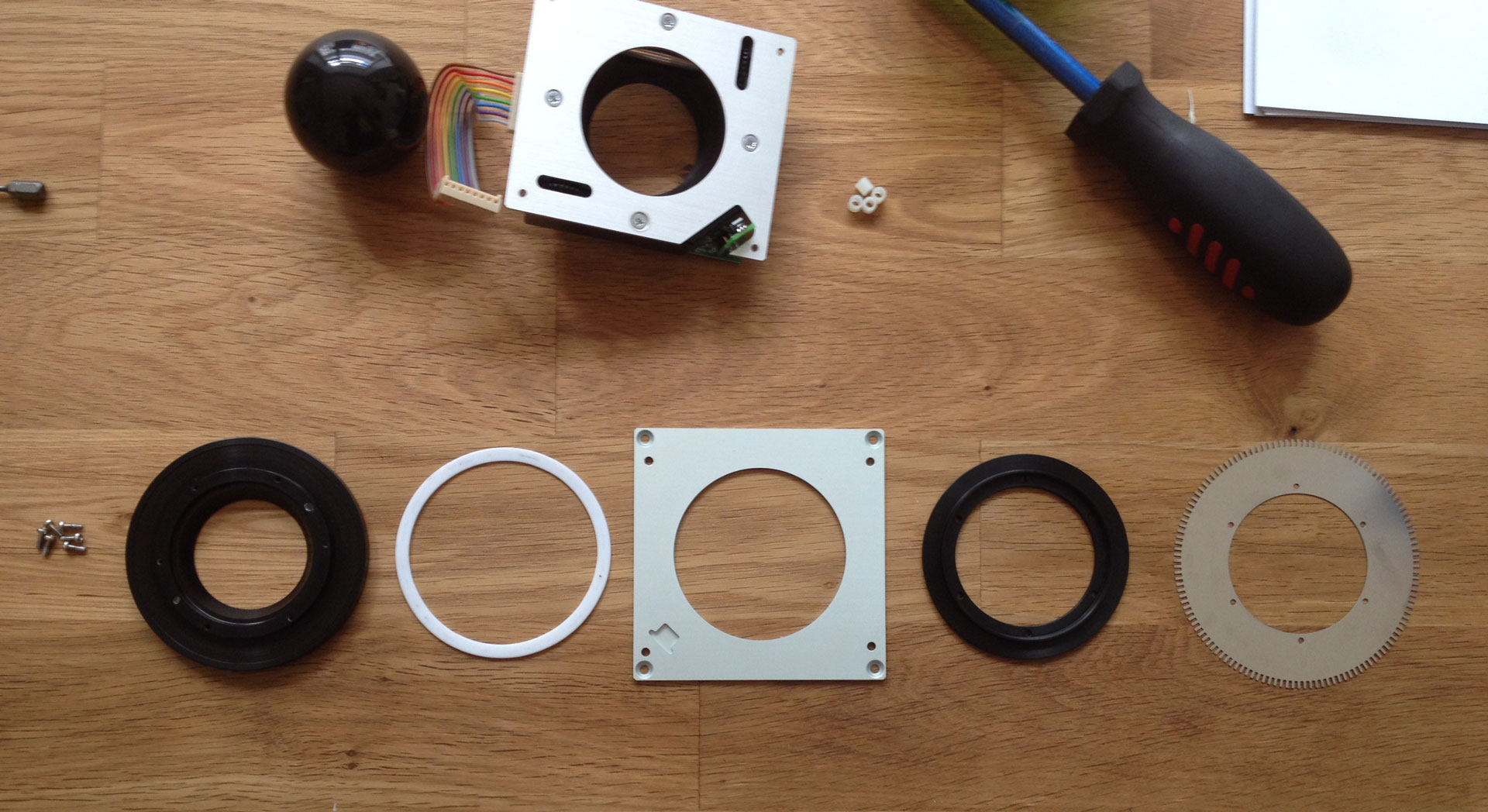

Once taken apart, you should have the 4 screws, 4 spacers, ball, ring-piece and caddy-piece.

Now my CP200 here is quite a bit old and still features roller-pickups for the balls.

The newer CP200 models feature laser-pickups, which of course, you better not touch, because those normally don’t need any cleaning.

But here we are with the rollers – clean them up with some cotton cloth – once clean take another piece of cotton,

and spray some silicone-spray on it and apply it to the rollers.

Done, rollers are fine now.

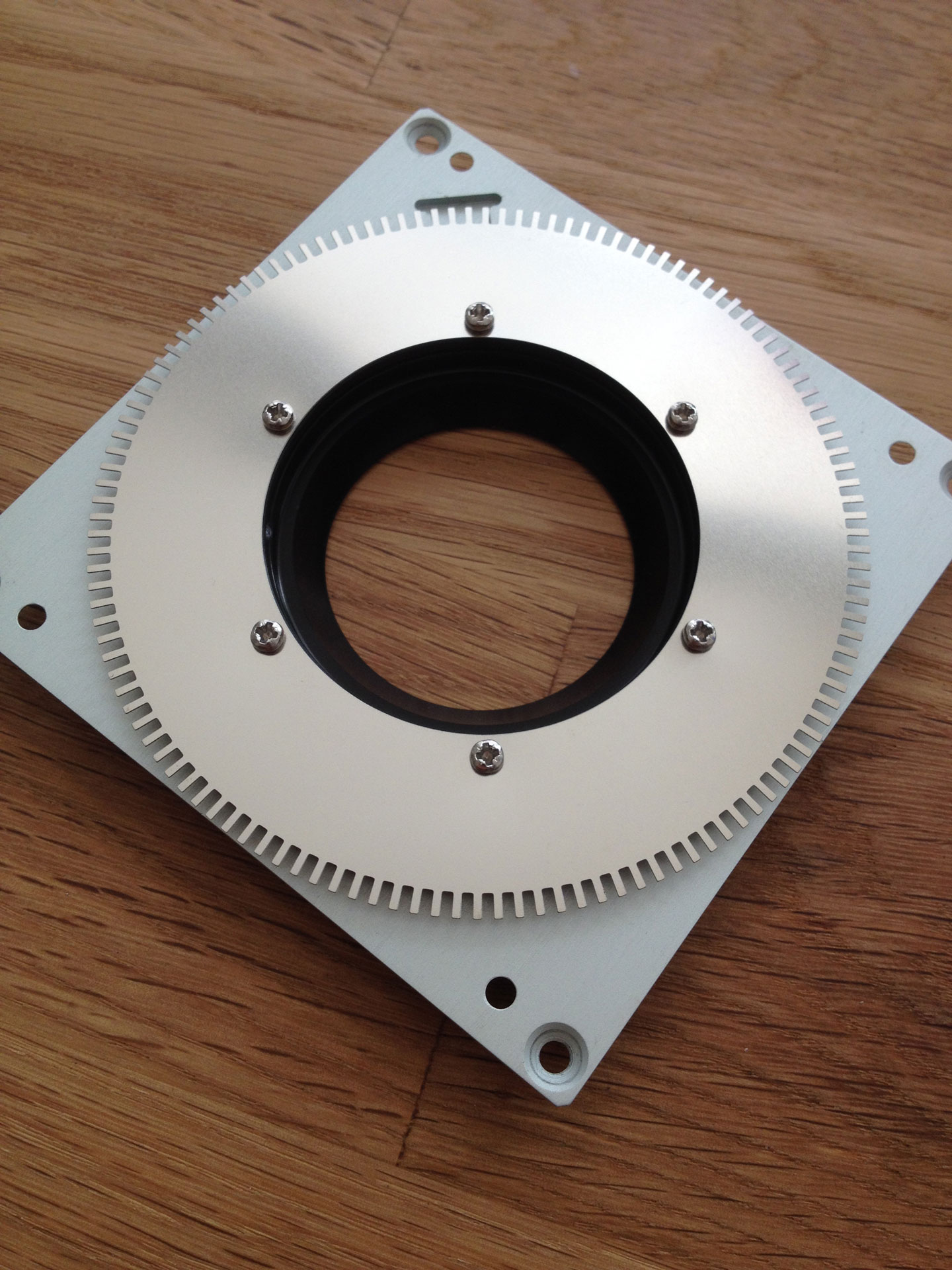

Next, loosen the 6 screws holding the metal sheet to the rings, and take the top completely apart.

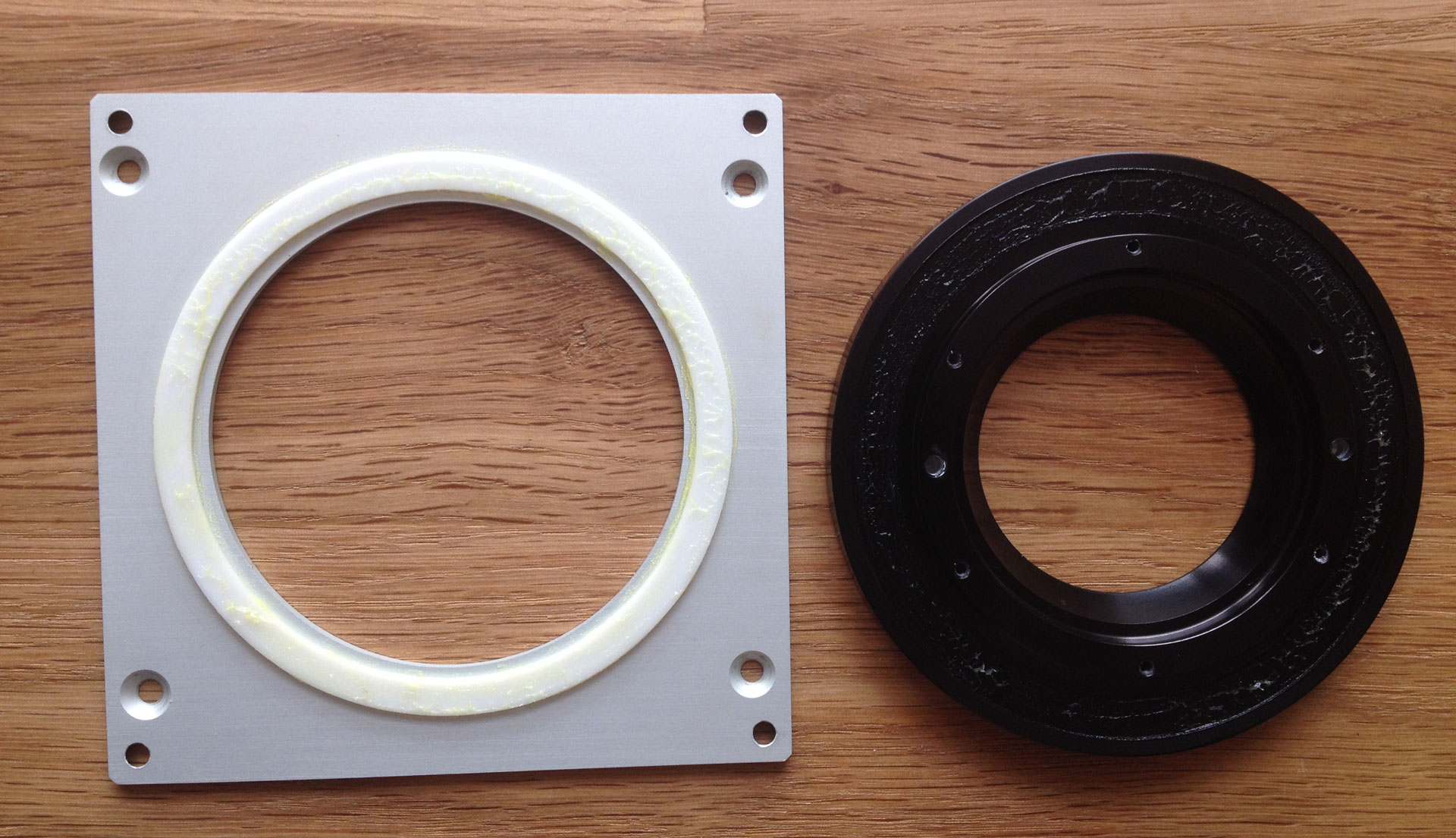

You should now have the ring itself, the plastic spacer, metal sheet and the counterpart for the ring.

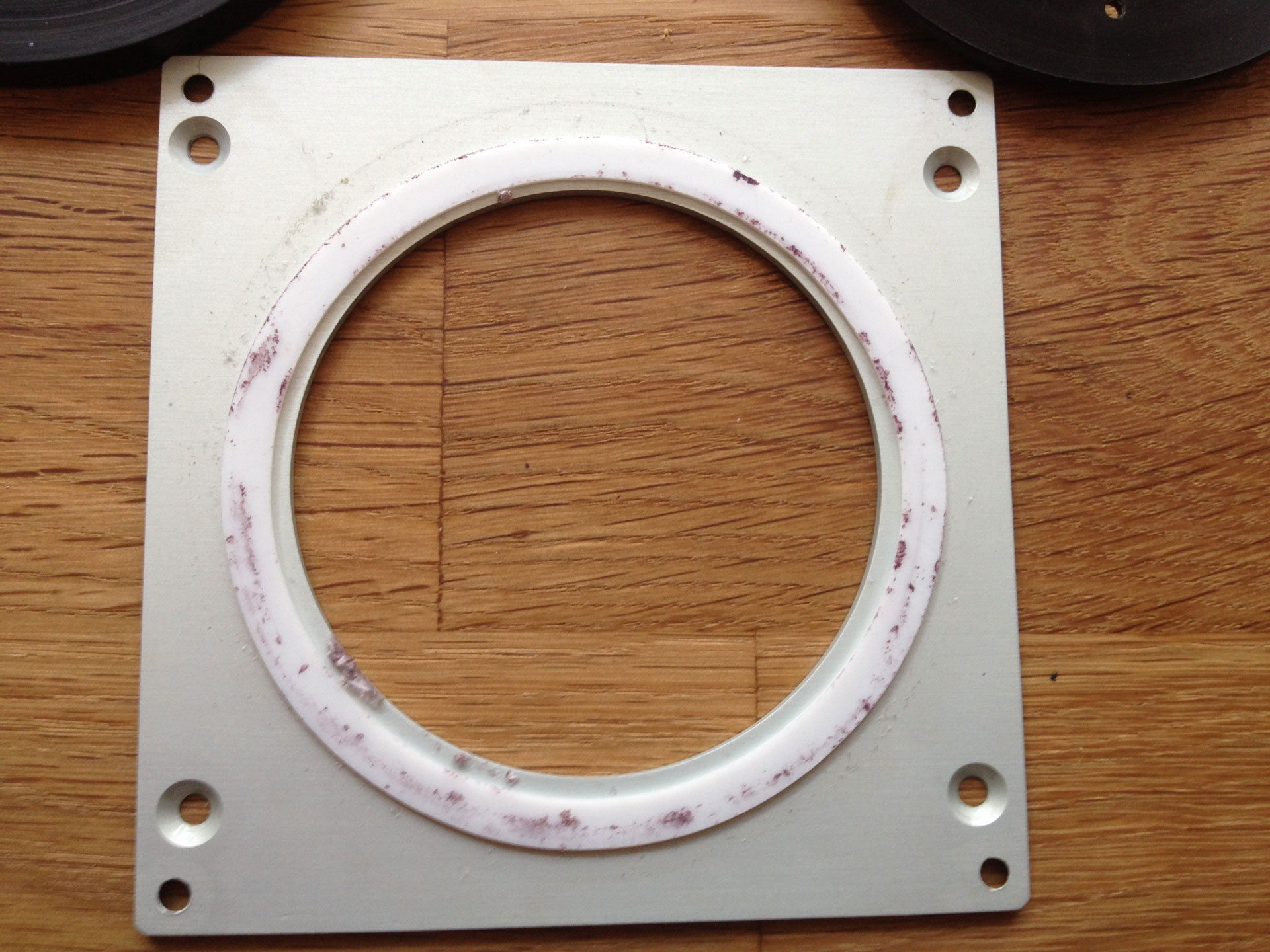

As you might notice, the white spacer-ring is quite dirty and the main cause for a „scratchy“ behaviour of the rings.

Clean up the black „dialplate“, counterpart of the ring, the aluminium plate and of course the white spacer-ring.

Next, put some of the grease onto the white spacer-ring and also on the black dialplate.

Don’t use too much grease – just have both covered nicely like in the picture.

Then put together dialplate, spacer, alu-plate and counterpart for the dialplate. Do not screw them together, but rather hold them together with your hands and slide the alu-plate around, to see if there’s still anything scratching, or if the behaviour is smooth enough.

Next, put everything back together in reversed order.

Before putting the ball back into the carrier, again spray some of the silicone-spray onto a piece of cotton cloth, and wrap it around the ball to apply it to the same.

Then put the ball inside the carrier and the top-plate together with the dialplate and everything back on top.

Be careful on that step – getting the metal sheet back into the read-element is a bit tricky, but rest assured, it’s totally possible without any force 😉 .

Everything else is pretty easy – place the spacers back in and mount the top-plate to the bottom of the caddy, then mount the complete caddy back into the panel – don’t forget to connect the rainbow cable back again. Proceed with the other two balls and at the end put back the bottom case again.

As said on the beginning – no rocket science 🙂 .

One last tip at the end – lately I have seen a couple of CP200-panels not working anymore (no ethernet connection possible, no ping possible).

The issue was almost always a defective network-interface inside the panel itself. This can easily be taken out and replaced by Tangent.

Cheers,

Mazze